ALUMINIUM DIECASTING

DESIGN AND CONSTRUCTION OF DIES

REWORKS AND MACHINING

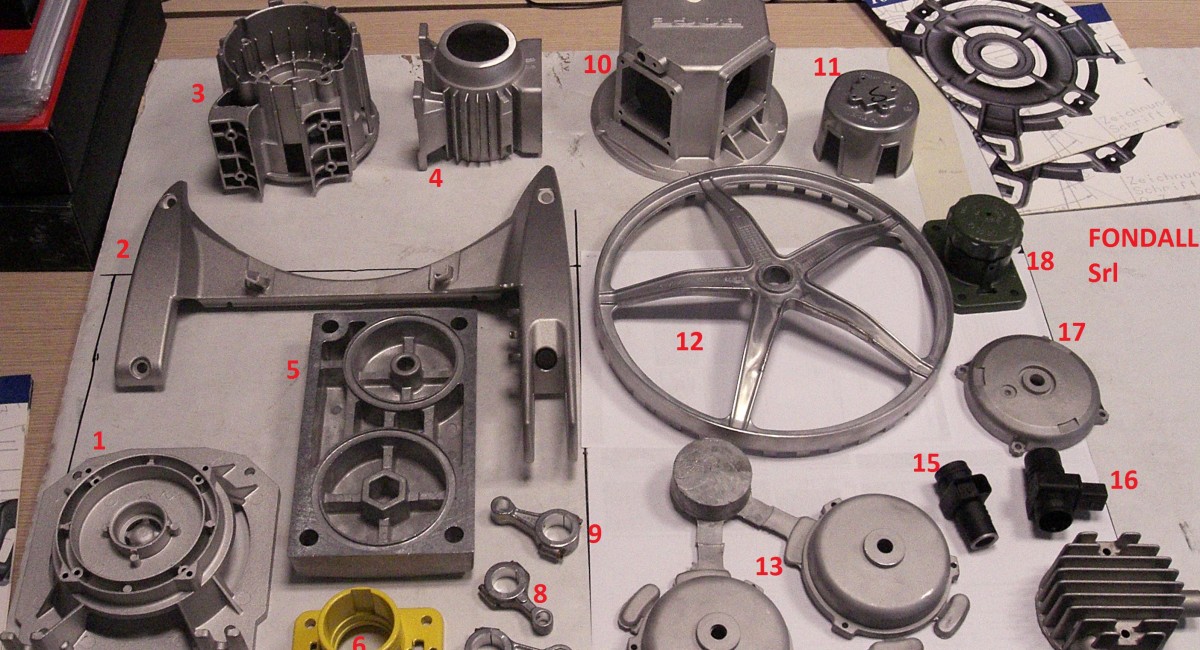

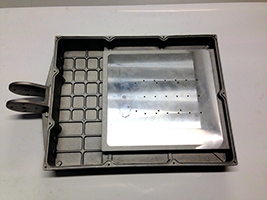

Since 1986 the company FONDALL has been specialized in ALUMINIUM DIE-CASTING. Our experience and skill, developped over the years, together with high-tech machinery and equipment, allows to satisfy every customer needs with the necessary precision and reliability. FONDALL can also make further high-quality finishing and machining on the die-pieces, such as: Trimming, Polishing, Vibro-tumbling, Sand-blasting, Drilling, Threading.

Moreover

FONDALL co-operates with a Company specialized in design and construction of Dies. In this way we can offer a full service to the customer from design to product testing,with pre-production and mass-production. Prime-quality precision products, competitive prices, respect of the agreed terms of deliveries, allows

FONDALL to be supplier of main Italian and European Companies in the sector of Automotive, White-goods, Furnishing, Household appliances, Mechanical. (All these companies certified with UNI EN ISO 9001).

FONDALL exports over 80% of ns. production in Austria, Germany, Switzerland, Netherlands France, Czech Rep., Slovakia.

The range of our fully automatic die-casting machines has different tonnages, from 180 to 600 tonn.

July 07: Our company has obtained the UNI EN ISO 9001:2008 Certification, for the Quality System management.

July 19: Our company has obtained the UNI EN ISO 9001:2015 Certification, for the Quality System management.

This important goal confirms Fondall primary objective to offers its customers only high quality products, at best prices.

Our quality policy

Equipment

Our experience and skill, developped over the years, together with high-tech machinery and equipment, allows to satisfy every customer needs with the necessary precision and reliability. FONDALL can also make further high-quality finishing and machining on the die-pieces, such as: Trimming, Polishing, Vibro-tumbling, Sand-blasting, Drilling, Threading.

Moreover FONDALL co-operates with a company specialized in design and construction of dies. In this way we can offer a full service to the customer from design to product testing,with pre-production and mass-production.

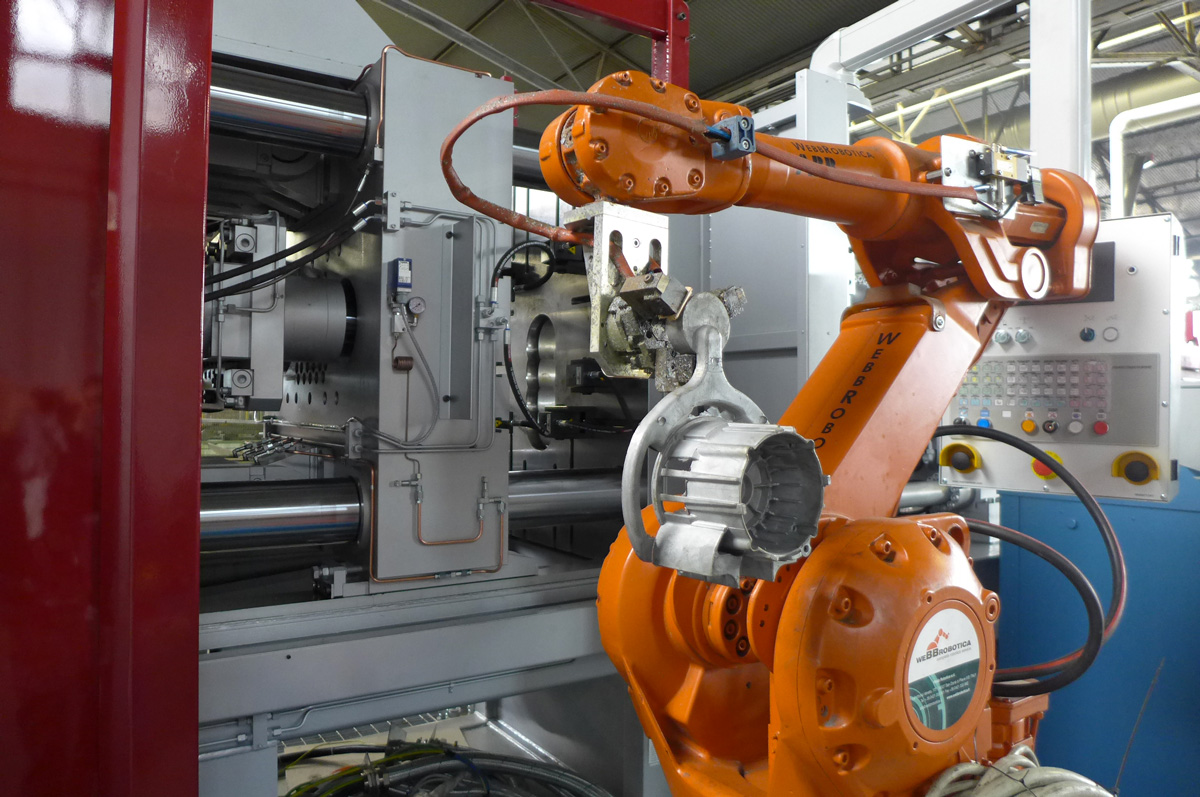

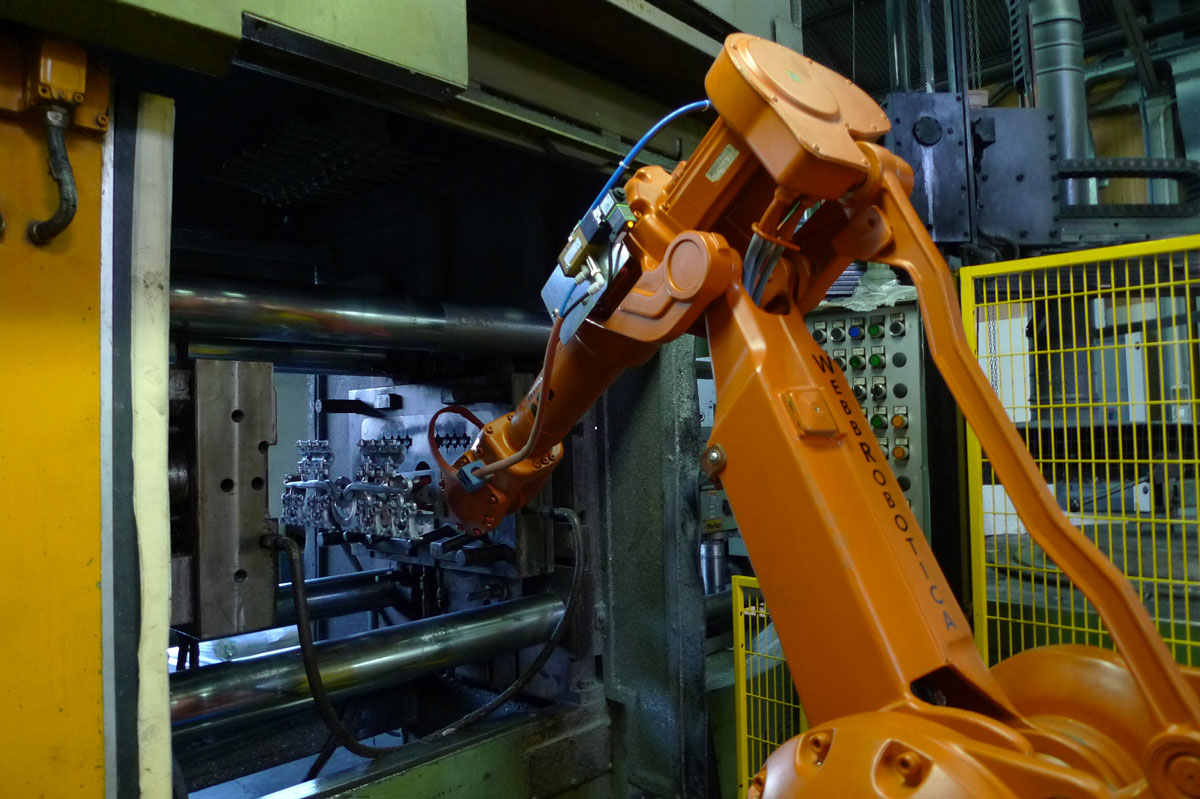

DIE CASTING MACHINES

-OLEPRESS OP 250

-MAICO 370 TON + ROBOT ABB IRB 2400

-COLOSIO 400 TON + ROBOT ABB IRB 2400

-MAICO 630 TON + ROBOT ABB IRB 2400

-MAICO 750 TON + ROBOT ABB IRB 2400

-MAICO 750 TON + ROBOT ABB IRB 4600

-MAICO 450 + ROBOT ABB IRB 2600

-HAITIAN 750 TON + ROBOT EFORT ER50-2100

*All the casting machines are aided with a THERMOREGULATOR device for the tool temperature control.

TRIMMING PRESSES

-nr. 1 TECNOPRESS KZP40 tonn.

-nr. 3 TECNOPRESS KZP 30 tonn.

-nr. 2 TECNOPRESS KZP 20 tonn.

-nr.1 TECNOPRESS KZP 15 tonn.

-nr.1 ROBOPRESS TS 40 tonn.

-nr.1 ROBOPRESS TS 30 tonn.

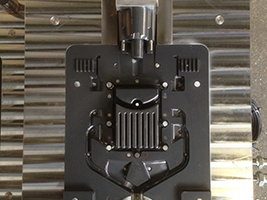

ROBOTIC FINISHING SYSTEM

Thanks to our experience and the technology of our robotic deburring system, we are able to manage long and complex deburring operations, guaranteeing a constant and homogeneous finish.

FURNACE FOR MELTING

MTX⁴ 100 model

Melting furnaces are the most metallurgically correct solution for melting aluminium. These furnaces allow the ingots to be melted while maintaining the original quality of the material, obtaining castings with fewer impurities. With this type of furnace, greater temperature stability of the aluminum and a lower environmental impact are also guaranteed.

MACHINING

-nr. 1 SABBIATRICE ( sandstrahlen machine— sandbalsting machine)

-nr. 2 BURATTATRICI ( trovaliziert machine- tumbling machine)

-nr. 2 TORNITRICI (drehmachine – lathe) OKUMA LB200 CAPACITA’ MAX DI TORNITURA D.230 mm

-nr. 1 CENTRO DI TORNITURA (CNC drehzentrum- CNC lathe center ) OKUMA LB200 M MOTORIZZATO CAPACITA’ MAX DI TORNITURA D.230 mm

-nr. 1 CENTRO DI TORNITURA A 4 ASSI (CNC drehzentrum- CNC lathe center ) OKUMA LT 200 M MOTORIZZATO CAPACITA’ MAX DI TORNITURA D.230 mm

-nr. 1 CENTRO DI LAVORO (CNC universal maschinen- CNC machining center) BRIDGEPORT A CAMBIO PALLET XR700 APC CORSA 700x500x450

-nr. 1 CENTRO DI LAVORO (CNC universal maschinen- CNC machining center) BRIDGEPORT WMC 760 XP3 CORSA 760x500x450

-nr. 2 CENTRI DI LAVORO PER ALTA PRODUZIONE(CNC universal maschinen- CNC machining center) BROTHER TC 32 BNQT A CAMBIO PALLET CORSA 550X450X400

-nr. 2 CENTRI DI LAVORO TAPPING CENTER(CNC universal maschinen- CNC machining center) BROTHER TC S2A CORSA 480x400x350

-nr. 1 TORNIO PARALLELO, (drehmachinen parallel- lathe machine)

-nr. 1FRESA UNIVERSALE ARNO NOMO, (frasemaschinen- milling machine )

-nr. 1 PRESSA IDRAULICA 50 t, (hydraulische presse- Hydraulic press )

-nr. 1 SEGA A NASTRO BIANCO 370 CNC (band sage – band saw)

-nr. 4 TRAPANI A COLONNA PER FORATURE DA 0.5 A 50 mm (bohrmaschinen – drill)

-nr. 1 MASCHIATRICE ( tapping machine )

-nr. 1 TRANSFER PER OPERAZIONI COMBINATE ( Transfer)

-nr. 1 LAVAPEZZI ( washing machine)

TOOLING SHOP

UFFICIO TECNICO

-stazioni di Mastercam 3d,Mastercam wire,Catia,Worknc,Visi-Cad e Cam 3d

FRESATRICI E CENTRI DI LAVORO

-DMC 210 cnc

-HERMLE 1000 cnc con 4 asse controllato

-HERMLE 850 cnc

-HERMLE 851 cnc

-HERMLE 700 cnc

-HERMLE U630cnc

-HRMLE MHAO 80 T 18.000 giri con 4-5 asse controllato

-COREA CF-20 cnc

-SACHMAN T 10 HS 200X 1075X 900 con testa e tavola girevole a cnc

TORNI:

-COLCHESTER MASCOT 1600 corse 2000

-COMM 200 corsa 1500

RETTIFICHE

-ALPA 1000 corse 1000x600xh350

-B.I. corse 700x300xh300

-MININI 8.13 1390x760x550

ELETTROEROSIONE :TUFFO E FILO

-AGIE PULS corse 420 x 320x 400

-AEG ELOTHERM corse 200 x 150 x150

-AEG ELOTHERM corse 900x 500 x 500

con 4 asse controllato

-CHARMILLES corse 600 x 400 x 180

TRAPANI:

-BERGONZI FM1000

-BERGONZI FM850

FORNO PER TRATTAMENTI

PROVASTAMPI E REPARTO VERNICIATURA CON ATTREZZATURA AD ULTRASUONI.

CONTACT

31010 Cimetta di Codognè (TV)

Italia

Fax: +39-0438-795510